Bio-ceramic is a high biofilm clay as the main raw material, blending a certain percentage of binder, pore forming agent, inorganic aggregate by the ingredients, sugar tablets into a ball, high temperature firing, sieving and a series of processing by the The spherical granular material. The main ingredients of partial aluminum silicate, dark brown or grayish brown, particle size according to different requirements. Efficient light ceramic biofilm structure in the physical performance of micro-rough and porous, these features enable efficient biofilm bio-ceramic is particularly suitable for micro-organisms on the surface of growth, reproduction. Full use of modern water treatment processes of these features, making it especially the sewage water treatment, micro-biological pretreatment of raw water pollution and water filtration technology, the ideal filter, coupled with its moderate density, high strength, abrasion, physical and chemical properties stability, not to water features such as the release of toxic and hazardous compounds, becoming the first choice of treatment media.

Media> ceramic filter production process are:

Raw materials, auxiliary materials → drying → recipes → crushed sugar granules → → → pre-sintering → cooling → drying → screening → Packaging → storage measurement

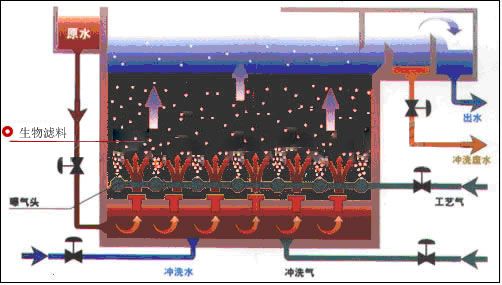

BAF technology is the core media> ceramic filter.

Excellent filter for easy hanging with a rough surface membrane, microporous, specific surface area suitable for rapid proliferation of microorganisms. As the packing density is moderate, easy backwashing and aeration, high cylinder pressure (≥ 4.5Mpa), can withstand prolonged high water shock loading. Effluent quality and stability, reduce operating costs.

After the company has improved formulation, extraction process, so 3uw-T series ceramic filter has the superior features:

1. Microporous surface, specific surface area (≥ 4m2/cm3), for a variety of microbial growth, on its surface to form a stable, highly active biofilm, high quality effluent.

2. Filter pore distribution, to overcome the uneven distribution due to pore filter head loss caused by a large, easy to plug, compaction of the defects.

3. Packing density is moderate, (0.75-0.95g / cm3) backwash easily, low energy consumption, do not run when the backwash material.

4. With a good aggregate grading (3-5mm, K60 ≤ 1.25; 4-6mm, K60 ≤ 1.38), dirt holding capacity, high utilization rate of filter head loss increased slowly, running a long cycle, water production large.

5. Strength, abrasion, physical, chemical stability, long life. Company filter> ceramic filter for high-temperature firing of clay as raw materials, long-term water immersion will not release any toxic and harmful substances, no secondary pollution. Controlled by the China Disease Control and Prevention for testing, compliance with drinking water distribution equipment.

6. Large-scale production, the price is cheap. The annual production capacity of thirty thousand cubic meters, to August to more than 40,000 cubic meters. Manufacture process, in all aspects of production, strictly from the particle size, uniformity, size distribution, density, particle shape, acid soluble rate, porosity, surface area, rubbing in various aspects of checks to ensure quality. Has been widely used in municipal sewage, industrial waste water and wastewater treatment in recent years is to develop the application in the water plant.

3uw-T Series Filter> ceramic filter, the use of a biological aerated filter (C / N) treatment of municipal sewage and effluent quality standards for wastewater discharge can be achieved (GB8978-1996) provided for levy of urban secondary sewage treatment plant-level standards. BAF by Sec (C / N filter N filter) treatment of municipal wastewater advanced treatment can play a role.

efficient bio-ceramic filter biofilm light technical parameters

|

project

|

performance and parameters

|

|

Appearance

|

spherical, surface dark brown or gray brown, rough and porous

|

|

size

|

<2.0mm

|

≥ 2.0mm

|

|

packing density

|

0.95 ~ 1.10g/cm 3

|

0.95 ~ 1.0g/cm 3

|

|

apparent density

|

1.4 ~ 1.8g/cm 3

|

1.4 ~ 1.8g/cm 3

|

|

accumulation porosity

|

≥ 35%

|

≥ 40%

|

|

breakage

|

≤ 0.03%

|

≤ 0.04%

|

|

wear rate

|

≤ 2.0%

|

≤ 3.0%

|

|

surface area

|

≥ 1 × 104 cm 2 / g

|

≥ 1 × 104 cm 2 / g

|

|

ignition

|

<0.03%

|

<0.03%

|

|

uniformity coefficient

|

K60: ≤ 1.40

|

K60: ≤ 1.40

|

|

hydrochloric acid soluble rate

|

≤ 0.10%

|

≤ 0.10%

|

|

clean filter head loss

|

<135mm / m

|

<125mm / m

|

|

leachables

|

contain no harmful trace elements

|

contain no harmful trace elements

|

|

crushing strength

|

≥ 23.4Mpa

|

≥ 23.7Mpa

|

efficient bio-ceramic filter biofilm light technical parameters

|

Index Name

|

Si O 2

|

Fe 2 O 3

|

Al 2 O 3

|

CaO

|

Mg O

|

Na 2 O + K2O

|

other

|

|

content (%)

|

60 ~ 75

|

6 ~ 10

|

15 ~ 22

|

2 ~ 5

|

1 ~ 4

|

1 ~ 5

|

1 ~ 3

|

ceramic filter application notes

ceramic filter are used in water supply projects. In order to maintain biological activity, filter backwash design must have device. Proposed oxygen aeration. Filter into the pool, should be cleaned with water, to filter the dust cleared, place the filter, note the choice of gradation. Ban on direct media stampede. When stacking a nuclear-free media, away from heat, avoid sun exposure and rain erosion.